(Re)Introductions and the Parts Coach

Written on February 18th, 2024 by George Beckstein

The “America” license plate makes it road legal in all 50 states

It has been quite a while! I haven’t posted in almost 3 years!

What have I been doing for so long? Well, a lot, to keep it short.

Between multiple job changes, buying a house, and rowing competitively in the Summer, I haven’t had much time to write and document my projects, including The Shack on Wheels.

I have slowly been moving my shop from my parents’ house while also getting my house unpacked, sorted, organized, etc.

However, in between all of that, I did make some time for MotorHome shenangigans!

There is much progress to update this blog with, and my goal is to write 1-2 posts a week: a retroactive blog post about something I did, and/or a current blog post about what I’m working on more recently.

I started today by updating this blog with a cool new feature: comments (powered by utteranc.es)! So now the whole of the internet can tell me what they think of my content 😁

So without further ado, let’s get on with my first post in almost 3 years!

The Reckoning, The SoW, and The Parts Coach

I realized last year that The Shack on Wheels project was taking too long. Admittedly, I may have been a bit optimistic about how long certain things would take (like designing multiple automotive ECUs in a custom CAN network).

It was a bit of a reckoning – I was under a lot of stress from work and life and I was losing motivation to finish the SoW. After taking a hiatus from the project, I made a consequential decision: I would finish the project but minimize the scope.

The oldest trick in the book when managing engineering projects.

There was (and is) so much to do already just to get the SoW back on the road, let alone functional and reliable as an RV again. On top of that, I was trying to electrify/modernize everything. I wanted the SoW to be absolutely pristine before it took its maiden voyage.

However, as everyone learns with age, our time on this Earth is finite; I’m now almost 30, better get a move on.

Hence the logic for my new strategy: Get the SoW back on the road as a functional RV and then tinker with it.

The Sow

Fortunately, before I burned myself out on the project, I finished most of the major mechanical restoration. The frame is rust-free, (mostly) new, and beautifully painted black. The engine has been returned to its original brilliant Oldsmobile metallic blue (and runs!). The front suspension, the rear suspension, the brakes, the tires. Everything is new or restored. It’s ready for another 50 years on the road.

I’d say it’s fit for a museum at this point. I’m very proud of the (semi) finished product. It is truly a beautiful piece of engineering.

I promise I will post more pictues in my upcoming posts.

I promise I will post more pictues in my upcoming posts.

So now, with the mechanical era of this project waning, I had to start planning what’s next in the coming era: the interior outfitting.

When I started the teardown of the original SoW, I was young and in my early 20’s, ready to take on the massive project of restoring an entire 70s RV. Or so I thought.

As happens with most projects, the scope kept expanding. At first, it was just a simple refresh. Fix the leaking roof rails, patch the rotted spots of the wood floor, and get it running and driving again.

When the frame turned out to be shot, the decision was made to do a frame-off. I don’t regret that decision. The SoW would have been an utter nightmare for long-distance traveling in terms of reliability and safety.

However, we also decided we would make a completely new interior for it from scratch. This was the mistake.

I am an electrical/software engineer with some mechanical ability. I am not a cabinetmaker or carpenter (though I am trying to get better at it). There is no way I will be able to make a more space-efficient, visually appealing, and functional interior than the original GM stuff. At least, not in a timely manner 😉

So, to all the told-you-so-ers out there (Dad), I admit it; I messed up. I destroyed and gutted the almost completely original interior of my GMC MotorHome. Shivers still run down my spine when I think of how I took a Sawzall to the bath module fiberglass to fit it out the door. It’s like a murder scene flashback… okay, maybe I’m being a bit dramatic.

Fortunately, I had the foresight to save a few items that I thought could have been sold or refurbished. So some cabinetry was saved. Along with all the cushions and bracketry for the fold out rear bed and Davo bunk-bed. Largely though, my original interior is gone. It wasn’t in perfect condition, but for 50 years old, it wasn’t in bad condition either.

In retrospect, I highly highly highly advise against tearing out the original GM interior. It is also pointless to remove the sprayed in insulation, unless it is truly pest-eaten. Even then, you can just patch the damaged areas.

However, we can’t undo the past, so now what?

The Parts Coach

The Parts Coach

The Parts Coach

In a stroke of luck, there happened to be the perfect parts coach for sale not too far away. I saw the listing on a GMC MotorHome Facebook group listing (yes, I still use Facebook so I can keep in touch with old people 😛).

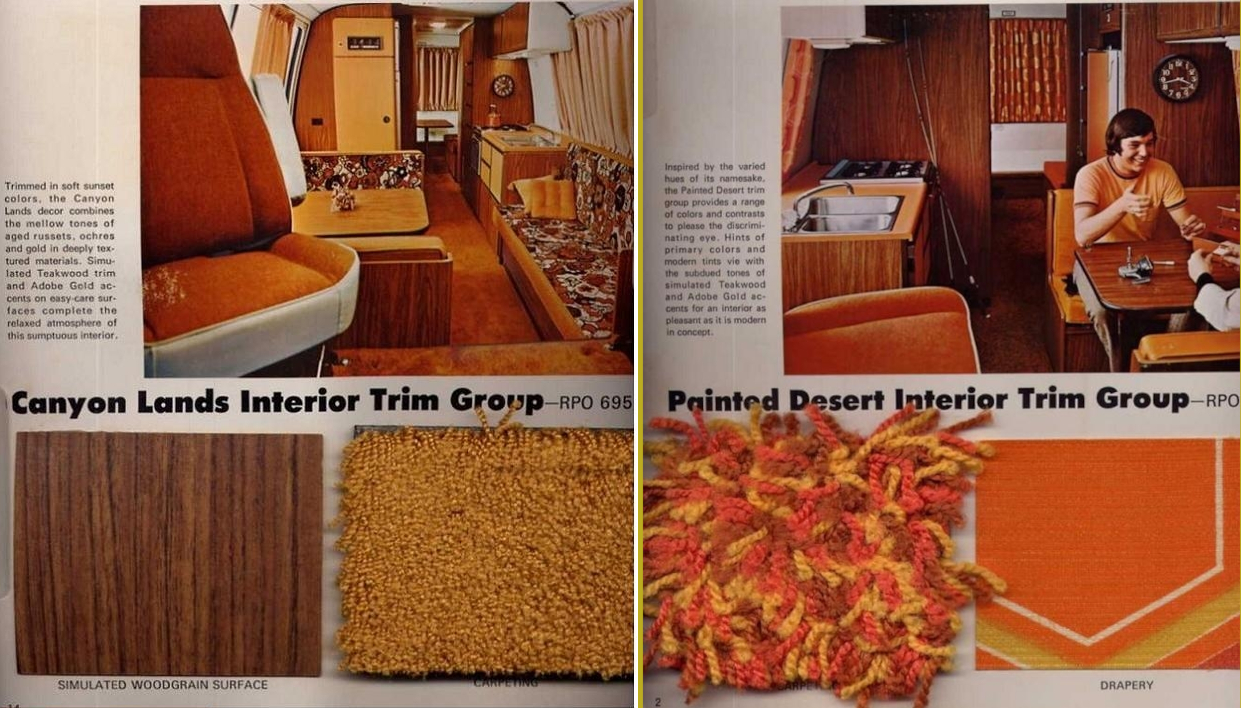

It caught my eye: 1973? Check. 200 miles away in Canton, NY? Check. It even had the largely identical interior color scheme to my Painted Desert, Canyonlands. In fact, this parts coach was only 69 serial numbers earlier than the SoW. They could’ve been at the production facility at the same time all those years ago… Maybe my grandparents even stepped into this very coach at a rally.

Canyonlands and Painted Desert shared largely the same interior finishes, including “Adobe Gold” laminate and Teakwood vinyl surfaces.

Canyonlands and Painted Desert shared largely the same interior finishes, including “Adobe Gold” laminate and Teakwood vinyl surfaces.

No title, no keys, not running, no matter.

It was a perfect opportunity.

Reinvigorated, I snatched the parts coach for an agreeable price ($600). That was the easy part. Now came the hard part. How in the world do I get a 10,000lbs, 26ft long, disabled bus all the way from Canton to Buffalo?

I called around (actually, my Dad would want me to mention that he called around for me 🙂), and after much searching, was able to find a local tow shop that agreed to do it. It wasn’t cheap, 3X the cost of actually purchasing the parts coach actually, but I decided to go with a local company that I could bang on the door of if there were any issues. And after the delivery experience, I was glad I did.

There’s a reason people sometimes give these things away – they’re expensive to move and scrap. Yes, that’s right, we still have to pay the scrapyard to take the shell when we’re done. And we have to pay to get it there!

Largely, the transporter was self-sufficient. Even with a non-functional air suspension system, they were able to winch the mammoth onto their Lo-Boy trailer. I was expecting a lot more phone calls and back and forth, but these guys knew how to move heavy machinery. Before I knew it, the coach was en route.

With a shortage of derelict-RV parking space available at my own house, my friend Andy agreed to let me park the parts coach at his shop while we tore it down. You see, he’s caught the GMC bug from me, and plans to use some of the parts from this coach in his own build 😁.

However, this presented a complication: Andy’s driveway is fairly narrow and about 200ft long. When the transporter arrived, it was dark (like, Winter night dark), and he was driving a gigantic, what looked to be a 1980s-era Kenworth semi truck.

There w’ain’t no way he was backin’ that rig up into Andy’s driveway (though I think a more experienced trucker probably could’ve handled it).

The unloading process took several hours. During the course of it, we discovered a couple things:

1.) The air suspension tank was completely rusted through and the entire system did not hold any pressure at all. While great from a “Carolina Squat” aesthetic point of view, this made unloading much more difficult.

2.) GMC MotorHomes are extremely hard to turn while stationary with no power steering. I felt like I was going to break the steering wheel (or my arms).

3.) Andy’s 80s Squarebody pickup truck (did I mention he was a GM fan?) can actually tow stuff. She don’t just look pretty.

4.) The GMC MotorHome toll windows are just barely big enough for my head to fit out of them.

5.) The brake lines were also rusted through, so we didn’t really have brakes either!

The way we finally accomplished this task was quite comedic, I’m sure. Several neighbors came by to spectate, some even helped!

She’s Squattin’

She’s Squattin’

With little other options, we hooked some tow chains up to the rear hitch of the parts coach and to Andy’s C10. While it does have a modern LS V8 in it, the frame (not to mention transmission) was not built to handle hauling 10,000lbs. We were apprehensive at first, but decided to give it a shot.

So with Andy driving the C10, me at the helm of the parts coach, and some neighbors and friends calling out instructions to us both, we slowly pulled the coach off the trailer. It was quite an arm workout for me, and quite a stress test for Andy’s C10. I’m sure Andy’s blood pressure spiked a little too 😉. The parts coach’s hitch dragged on the street and left a nice groove in the pavement. Oops.

As I carefully steered the disabled coach, Andy and his C10 pulled us down the long driveway. I was pretty shocked it worked. Andy’s C10 earned my respect that day as a real truck. We joked, “you finally hauled something with that trailer queen.”

This grainy black and white photo is the only known evidence that Andy’s C10 has ever actually towed anything 😛

This grainy black and white photo is the only known evidence that Andy’s C10 has ever actually towed anything 😛

I was glad to have gone with a local company though. While the C10 got it down the driveway, it was blocking Andy’s garage access. So we worked out for the transporter to return with a smaller tow truck and shimmy it into a more convenient spot. Begrudgingly, but true to their word, the transporter arrived a few days later to take care of it.

And with that, the parts coach was ours. We were ready to begin the salvage operation.

She’s a beaut, Clark

She’s a beaut, Clark

That’s It For Now

In my next blog posts, follow along as Andy and I document our teardown of the parts coach.